DNTPD >99% – High-Purity Material for Hole Injection and Transport Layers in OLED Applications

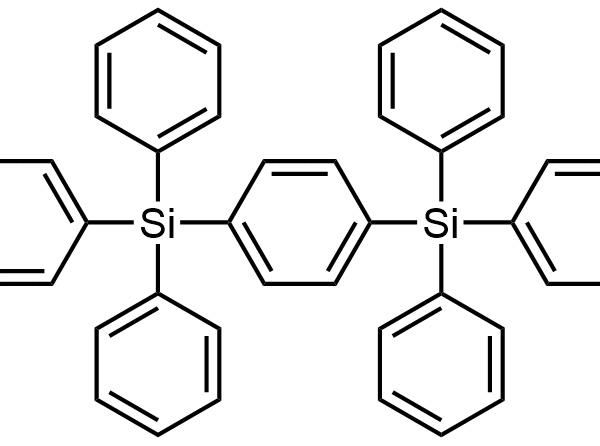

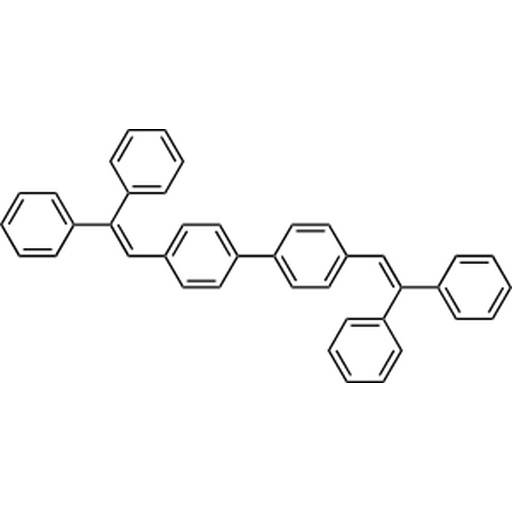

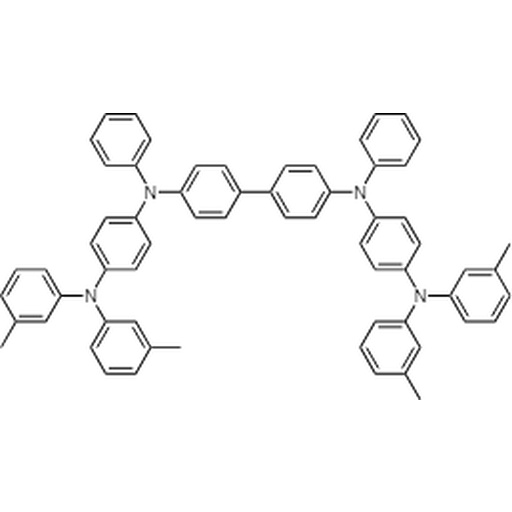

Noctiluca presents DNTPD (N1,N1′-(Biphenyl-4,4′-diyl)bis(N1-phenyl-N4,N4-di-m-tolylbenzene-1,4-diamine)), a premium-grade compound essential for advanced organic light-emitting diode (OLED) technologies. Formally known as N,N’-Bis{4-[bis(3-methylphenyl)amino]phenyl}-N,N’-diphenyl-4,4′-biphenyldiamine, with the molecular formula C₆₄H₅₄N₄ and CAS number 199121-98-7, DNTPD is meticulously synthesized to support cutting-edge OLED devices. With high purity (>99% HPLC) and optimized electronic properties, DNTPD is a crucial material for hole injection layer (HIL) and hole transport layer (HTL) applications, ensuring efficient charge balance and device performance.

Molecular Structure and Properties of DNTPD

DNTPD is a sophisticated organic compound with a molecular weight of 879.10 g/mol, presented as a yellow powder or crystalline substance. It exhibits an absorption maximum (λₘₐₓ) at 326 nm and photoluminescent emission (λₘₐₓ) at 473 nm, both measured in dichloromethane (DCM). The compound’s HOMO and LUMO levels of 5.1 eV and 2.1 eV, respectively, are specifically engineered to facilitate efficient hole injection and transport in OLED applications. Additionally, its thermal stability, with a decomposition range between 105–112°C (TGA), makes it suitable for demanding manufacturing and operational conditions.

Key Features of DNTPD

- Exceptional Purity and Quality: DNTPD is sublimed to achieve a purity level exceeding 99% (HPLC), ensuring high reliability and consistency in OLED applications.

- Optimized for Hole Injection and Transport Layers: Designed for HIL and HTL applications, DNTPD provides efficient hole injection and transport, contributing to improved charge balance and enhanced OLED performance.

- Superior Photophysical Properties: DNTPD demonstrates an absorption maximum of 326 nm and a photoluminescent emission peak at 473 nm, supporting advanced optoelectronic applications.

- High Thermal Stability: With a decomposition temperature range of 105–112°C, DNTPD maintains its structural integrity and performance under various fabrication and operational conditions.

- Versatile Compatibility: DNTPD is compatible with multiple deposition techniques, including solution processing and vacuum deposition, making it suitable for both research and industrial-scale OLED manufacturing.

The Role of DNTPD in Advanced OLED Technologies

DNTPD is a pivotal material in OLED architectures, playing a critical role in hole injection layers (HIL) and hole transport layers (HTL). Its optimized HOMO/LUMO levels ensure efficient hole injection from the anode to the emitting layer, reducing energy loss and enabling balanced charge transport. This, in turn, improves device brightness, efficiency, and longevity. The compound’s photophysical and electronic properties make it an ideal candidate for next-generation OLED displays and lighting systems, where precise charge management is essential for achieving high performance and energy efficiency. DNTPD supports the development of vibrant and reliable OLED devices that meet the stringent demands of modern consumer and industrial applications.

Conclusion:

Noctiluca’s DNTPD >99% underscores our commitment to delivering high-performance materials tailored for advanced OLED applications. With exceptional purity, thermal stability, and optimized charge transport properties, DNTPD empowers researchers and manufacturers to achieve groundbreaking advancements in OLED displays and lighting technologies. Discover how DNTPD can elevate your optoelectronic projects and bring your OLED designs to the forefront of innovation.